Precision agriculture relies heavily on accurate positioning to optimize farming operations. EFIX provides advanced solutions for this sector, particularly with their GPS base station systems. These stations serve as a reliable reference point, ensuring that farmers can achieve consistent accuracy in planting, fertilizing, and harvesting. By integrating GPS base station technology into daily agricultural practices, field managers gain access to high-quality positioning data that supports better decision-making and resource management.

Improving Crop Management through GNSS Tracking

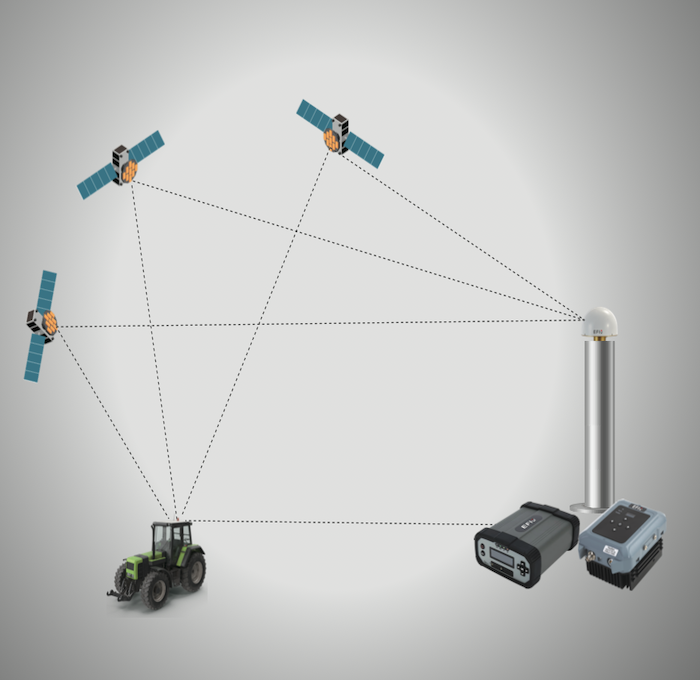

The integration of EFIX’s GPS base station into precision agriculture allows for improved monitoring and management of crops. With their 624-CHANNEL ADVANCED GNSS TRACKING, the F-NET Pro GNSS simultaneously receives signals from GPS, GLONASS, Galileo, BeiDou, and SBAS satellites. This full constellation coverage ensures superior GNSS raw data, which directly contributes to accurate mapping of fields and tracking of farm machinery. By leveraging this data, farmers can adjust irrigation schedules, optimize fertilizer application, and reduce operational errors caused by inaccurate positioning.

Supporting RTK Networks for Maximum Accuracy

One of the key benefits of deploying EFIX GPS base station systems in agricultural settings is the support for RTK networks. The F-NET Pro GNSS reference stations act as the foundation for real-time kinematic (RTK) corrections, enhancing the precision of GNSS rover positioning across large farms. This ensures that autonomous tractors, sprayers, and harvesters can operate with centimeter-level accuracy, improving efficiency and reducing resource waste. They combine robust hardware with seamless integration into existing farming networks, offering both reliability and performance.

Conclusion: Advancing Modern Agriculture

In conclusion, EFIX’s GPS base station solutions provide the backbone for precision agriculture operations. By utilizing 624-CHANNEL ADVANCED GNSS TRACKING and full satellite constellation coverage, they deliver accurate and reliable positioning that enhances crop management, operational efficiency, and resource conservation. The adoption of these systems supports modern agricultural practices, ensuring that farmers can make data-driven decisions and achieve consistent results in every field.